Knotless netting is net fabric without knots by interweaving strands or threads. According to the manufacturing process, it can be divided into 6 major types, that is, warp knitted netting, twisted knotless netting, plain netting, Leno/Gauze weave, plastic moulding netting and super knot netting. Here we'd like to introduce every process, features and applications.

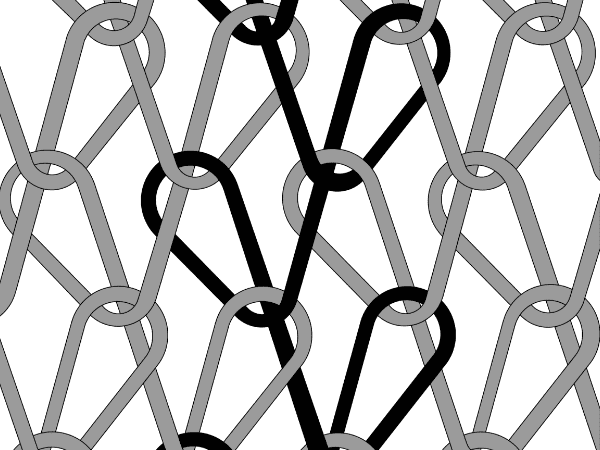

It is a net fabric composed of two adjacent strands or threads to form loops along the longitudinal direction of the net (warp direction), and alternately knitted with each other, so it is also known as Raschel net. It is produced by warp knitting machines and is made of PE monofilament yarns, PA multifilament yarns, PET multifilament yarns, PP multifilament yarns, etc.

Features

Application

In the fishing industry, it is mainly used as cage nets, purse seines and scallop cultivation nets. In addition, it is also used as construction safety net, dust control nets, anti bird nets, wind protection nets, sun shade nets and vegetable nets, etc.

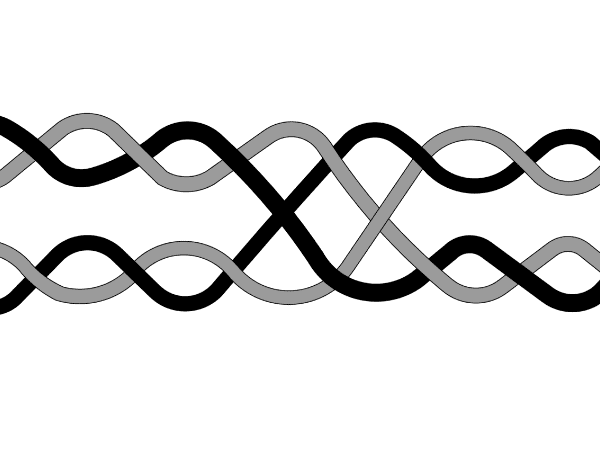

It is a net fabric composed of two adjacent strands after interweaving and twisting. It can be made of PE monofilament yarns, PA multifilament yarns, PET multifilament yarns, PP multifilament yarns, etc.

Features

Application

In the fishing industry, it is mainly used as cage nets, purse seines, etc.

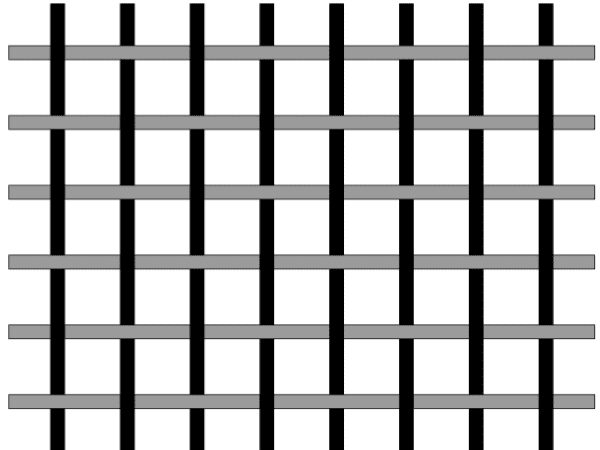

It is a plain cloth like net fabric interwoven by alternative warp and weft strands. It is mainly made of PE monofilament yarns.

Features

Application

It can be used as insect screens, package bags, etc.

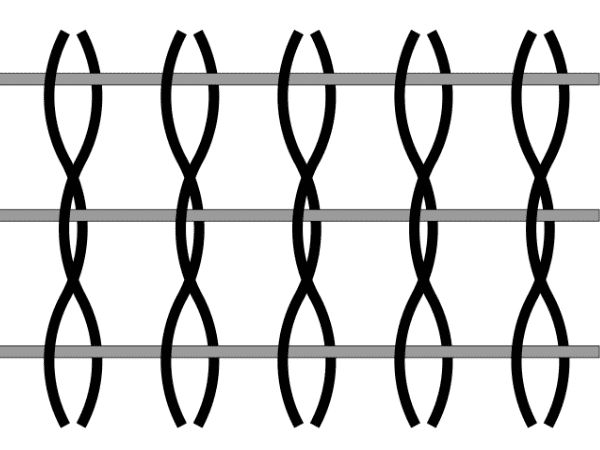

It is net fabric made by inserting weft threads into warp threads after twisting. It is mainly made of PE monofilament yarns.

Features

Application

Currently, it is mainly used for silverfish fishing, shrimp farming, shellfish farming, eel farming, lobster farming and crab farming.

It is a net fabric formed by directly extruded thermoplastic synthetic material after drawing. It is generally made of PE, PET and PA.

Features

Application

In agriculture, it can e used as chicken netting, plant climbing nets, anti bird nets. In addition, it is also widely used in aquaculture and other fields.

It is a net fabric made of two adjacent yarns after crossing and braiding. It is generally made of PA and PP multifilament yarns.

Features

Application

It is suitable for used as trawling and aquaculture netting.